Magnum Label was a new initiative of Mr. Raja and brought into legal existence during the financial years of 2013 & 2014.

Mr. Raja our founder took to this venture as his profound experience with the printing industry through his successful pioneering of “Raj Prints” for over two decades.

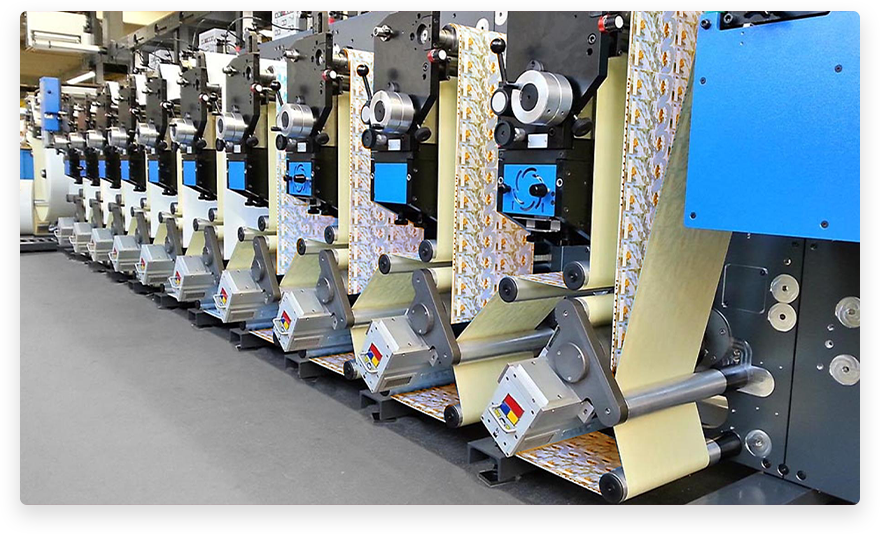

Magnum Label today is one of the Bangalore based leading name in the field ofb professional label printing across may verticals’ ranging into FMCG, Food, Parma, Beverages, cosmetic, industrial, airlines, electronics, automotive, Packaging & logistics to just name a few.

Magnum Label is a well known and accredited label printer and convertor, with strong technical associations with many world class materials’ suppliers. Magnum Label is proudly placed amongst the top ten label manufacturers in India.

The fully equipped in house testing facility with well qualified laboratory personal make sure that near zero defect output with consistent quality and timely delivery each time and every time is made possible to each client.